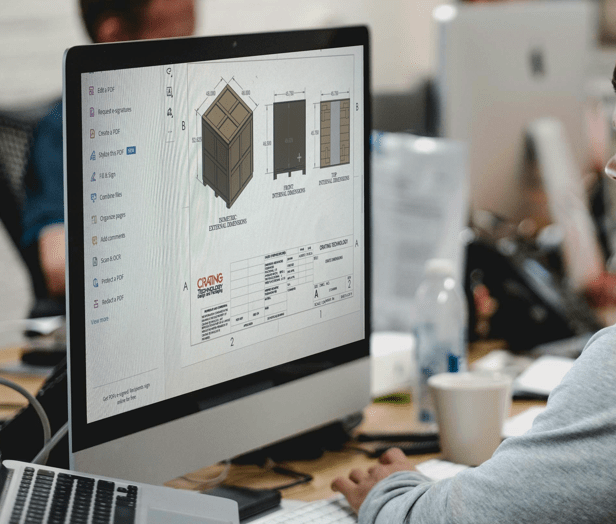

3D design in crating utilizes Computer-Aided Design (CAD) and modeling software to create detailed, three-dimensional representations of custom crates and their contents. This approach enables designers to:

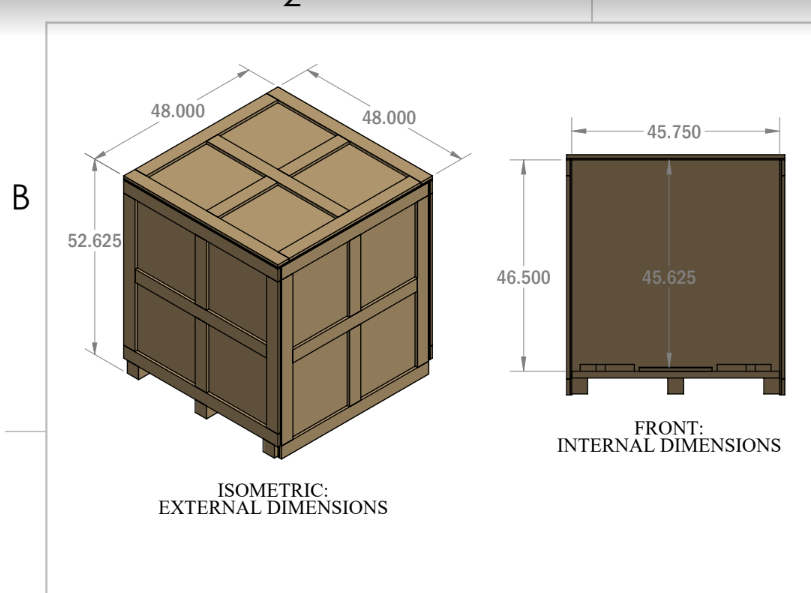

- Map out the dimensions of the item and the crate with exacting precision.

- Test various layouts and configurations to optimize protection.

- Identify potential design flaws before production.

By visualizing the crate and its components digitally, businesses can ensure their packaging solution is tailored to the unique needs of the item being shipped.

The Benefits of 3D Design for Custom Crating

Integrating 3D design into the crating process offers several advantages, transforming how crates are designed, manufactured, and used:

- Precision and Accuracy

- 3D modeling captures the exact dimensions and specifications of the item, eliminating guesswork. This ensures the crate fits the product perfectly, minimizing the risk of movement or damage during transport.

- Enhanced Visualization

- With 3D design, clients can see a realistic representation of the crate and its protective features before it’s built. This provides confidence that the solution will meet their requirements.

- Customization Flexibility

- The digital design process makes it easy to adjust dimensions, materials, and cushioning features on the fly. This flexibility allows for rapid prototyping and refinement.

- Cost Efficiency

- By identifying potential issues during the design phase, 3D modeling reduces waste in materials and rework costs. It also ensures the optimal use of resources like foam, wood, and hardware.

- Streamlined Collaboration

- 3D designs can be shared digitally with clients, engineers, and production teams, improving communication and speeding up approval processes.

How 3D Design Works in Crating

The process of integrating 3D design into crating involves several key steps:

- Item Measurement and Analysis

- Designers begin by collecting detailed measurements and specifications for the item to be shipped. This includes size, weight, shape, and any sensitive features that require special protection.

- Digital Modeling

- Using CAD software, the designer creates a 3D model of the item. Next, they design a crate around it, incorporating protective features like foam inserts, shock mounts, and securement brackets.

- Simulation and Testing

- The software allows designers to simulate the crate’s performance under stress. Factors like load distribution, vibration resistance, and shock absorption can be tested to ensure the crate meets performance standards.

- Client Review and Approval

- The 3D model is shared with the client for review. Adjustments can be made easily at this stage, ensuring the final product aligns with the client’s needs.

- Production and Implementation

- Once the design is approved, the digital specifications guide the manufacturing process, ensuring the crate is built to exact standards.

Applications Across Industries

3D design is particularly beneficial in industries where custom crating is essential:

- Aerospace: Precision-fit crates for irregularly shaped components, such as turbine blades or avionics systems.

- Healthcare: Detailed designs for crates transporting sensitive medical equipment.

- Defense: Military-grade crates requiring compliance with specific regulations.

- Semiconductor: Ultra-precise crates for cleanroom-certified items.

- Automotive: Custom designs for engines, glass, and specialty parts

3D Design and Sustainability

In addition to its practical benefits, 3D modeling supports sustainability efforts in the crating industry:

- Material Efficiency: The design process minimizes material waste by ensuring the crate is the exact size required for the shipment.

- Reuse Planning: Reusable crates can be designed with durability and long-term use in mind.

- Reduced Carbon Footprint: Accurate designs lead to more efficient shipping, reducing unnecessary bulk and weight.

Future Trends in 3D Crating Design

The evolution of 3D design technologies continues to enhance the crating industry. Emerging trends include:

- Augmented Reality (AR) Integration: Using AR to visualize crates in the physical space before production.

- AI-Driven Optimization: Leveraging artificial intelligence to analyze designs and suggest improvements for protection and cost efficiency.

- Automation in Manufacturing: Using digital models to drive automated production systems, increasing speed and accuracy.

Precision in every detail! This custom crate, designed using SolidWorks, demonstrates our commitment to engineering excellence for secure and efficient shipping solutions. From delicate electronics to oversized equipment, we tailor every design to meet your specific needs.

Conclusion

3D design is revolutionizing the crating industry, enabling unparalleled accuracy, efficiency, and customization. By visualizing the perfect fit before production, businesses can achieve greater protection for their valuable items while streamlining costs and improving sustainability.

If you’re ready to harness the power of 3D design for your crating needs, contact a trusted crating specialist today. Whether it’s a one-of-a-kind shipment or a scalable solution, 3D modeling ensures you’ll get the perfect crate, every time.

Would you like to explore 3D design for your next project? Let’s create a custom crating solution tailored to your exact requirements!