When people think about crating, they usually picture the end product: a strong wooden crate, perfectly sealed, maybe wrapped in plastic or shrink film, with sensitive equipment safely tucked inside. What they don’t see is the thought, planning, and collaboration that happen long before any wood hits the saw. This crucial preparation is part of our crate design review process, which lays the groundwork for everything that follows.

At Crating Technology, we treat each crate as a custom-built solution—because that’s exactly what it is. Before we begin building, we go through a detailed process to ensure the final product performs exactly as needed: protecting your equipment, meeting shipping and regulatory requirements, and simplifying your work on both ends of the journey.

Whether you’re shipping a single item or coordinating a full site deployment, the project’s success often depends on what happens early on.

Here’s what that process looks like behind the scenes—and why it makes such a big difference.

Step One: We Start with the Right Questions

Our work begins with a conversation, not a quote. When you contact us for a custom crate, we ask a series of questions to uncover more than just basic specs. Yes, we’ll gather dimensions, weight, and the shipping destination—but we also dig deeper.

To get it right, we start by asking the right questions:

• How will the crate be loaded and unloaded?

• Will it be exposed to moisture, heat, or vibration?

• Is the product fragile, top-heavy, or irregular in shape?

• Does it need to meet industry regulations—like MIL-SPEC, ITAR, or cleanroom compliance?

Sometimes, we get involved even earlier—especially when the item is still in development or undergoing final QA. If you’re unsure about the level of protection required, we’ll help you figure it out. We’ve worked alongside engineers, production teams, and logistics managers to solve problems before they occur.

This discovery phase sets the tone for the entire build. It lets us deliver a solution that’s not just functional, but thoughtful—designed around how your product actually moves through the world. And that’s exactly what makes our crate design review process so effective.

Step Two: Our Team Engineers a Smarter Solution

With all the details in hand, our engineering and production teams begin shaping the design. This stage draws on our experience, materials knowledge, and hands-on problem-solving.

Our crate design review process always includes more than one set of eyes. We bring in foam specialists, logistics coordinators, and on-site crating crews as needed to evaluate the plan and offer insight. Why? Because cross-functional input leads to better outcomes. A crate that seems perfect on paper might be hard to unpack at the destination—or require a forklift the client doesn’t have. We think through all of that.

The Crating Technology team also considers:

• Can we make the crate lighter without compromising strength?

• Will the internal bracing withstand multiple modes of transport?

• Does the foam system properly absorb shock or resist static?

• Can this crate be reused, collapsed, or modified for future shipments?

We don’t just build containers—we design systems that support your operations, protect your assets, and keep your project moving.

Some projects involve one-time shipments. Others support recurring logistics, multi-stop installs, or trade show rotations. In every case, the design reflects real-world conditions—not just the item itself. That’s the strength of a well-run crate design review process.

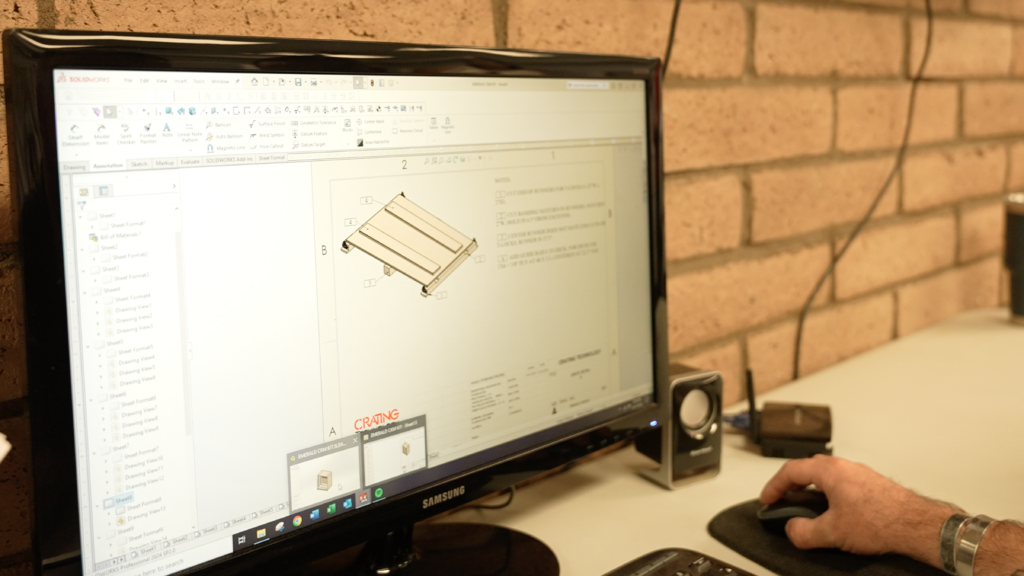

Step Three: We Model It Before We Build It

Before production, we often create CAD drawings or 3D models of the crate and internal packaging system. This proves especially valuable for complex equipment, highly sensitive items, or projects needing internal approvals.

Digital modeling allows us to:

• Visualize how the item fits with foam and bracing

• Identify weak points or stress areas ahead of fabrication

• Share clear layouts with your team or third-party handlers

• Confirm the crate meets structural or compliance standards

These drawings go beyond technical—they’re collaborative. We walk through the design with you (or your engineers) to ensure everything works. When required, we can also provide stamped drawings for regulated shipments or government-related projects.

This visual planning streamlines workflows on the receiving end too. Whether your equipment heads to a lab, remote field site, or cleanroom, we aim to make the uncrating process as smooth and intuitive as possible. That’s another key strength of our crate design review process.

Why Our Crate Design Review Process Works

Cutting corners during design might save time upfront, but costs more later. We’ve seen the consequences of crates built without proper planning: damaged goods, customs rejections, misaligned foam, or structures that don’t survive transit.

Our crate design review process prevents those issues. It functions as quality control, a communication tool, and a strategic step rolled into one. It ensures your shipment arrives safely, meets standards, and makes your team’s job easier from start to finish.

It also enables better collaboration. We’ve worked with procurement teams managing deadlines and aerospace engineers focused on tilt thresholds and tolerances. Bringing the right voices in early helps us design crates that solve problems—not create them.

Final Thoughts: Why Smart Crating Starts Early

At Crating Technology, we don’t just build crates—we build confidence.

At Crating Technology, we don’t just build crates—we build confidence.

Clients trust us with high-value, mission-critical equipment because we take time to design every crate with care. Because it matters. Whether your shipment is local or global, we want you to feel confident knowing every detail was considered before anything was built.

That’s where true protection starts—not in the woodshop, but at the whiteboard. And we wouldn’t have it any other way.

So if you’re preparing a shipment that’s valuable, complex, or simply too important to risk, let’s talk. We’ll walk you through our crate design review process and show you how we protect what matters most.